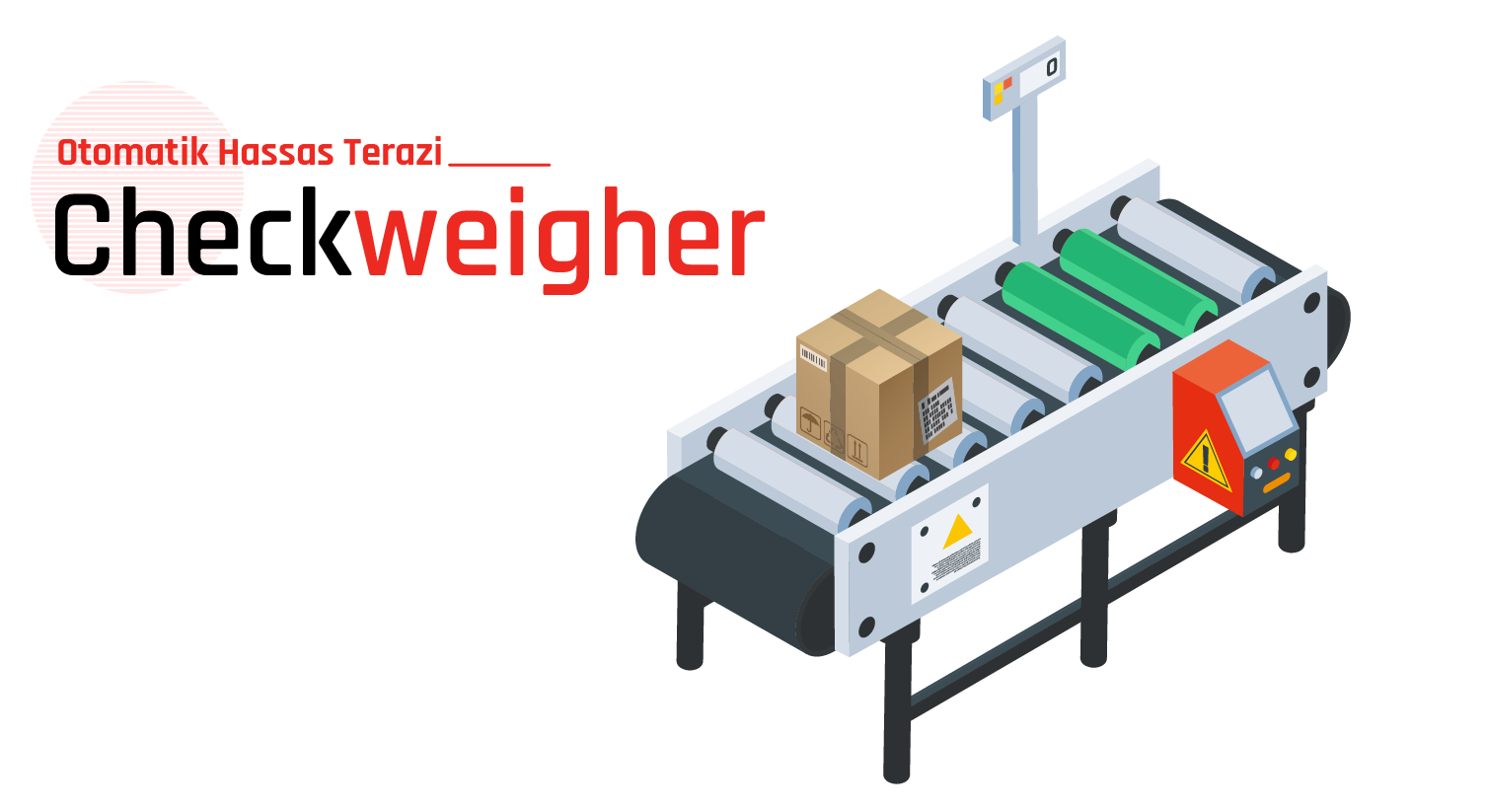

TraceArt Checkweigher is a type of industrial weighing device that quickly and accurately measures the weights of products and checks these measurements within a specified tolerance range. Checkweighers are often used in production lines or packaging processes. These devices are used to verify that products have the correct weights, detect weight deviations, and separate faulty products. In the TraceArt production line, products moving on the line have their weights measured, and products with weights outside the specified intervals are automatically removed from the line.

The key working principle and components of the automatic scale are as follows:

It includes weighing units or weight sensors that accurately measure the weight of the products.

There is a control unit that compares the measured weights and processes the data. This unit provides an alarm in case of weight deviation and controls the separation process.

It includes a mechanism used to determine whether products are accepted and to separate products with weight deviations. This mechanism can work using various methods such as air jets, push arms, or belt redirection.

There is an HMI panel for operators to monitor the Checkweigher, make adjustments, and observe the data.